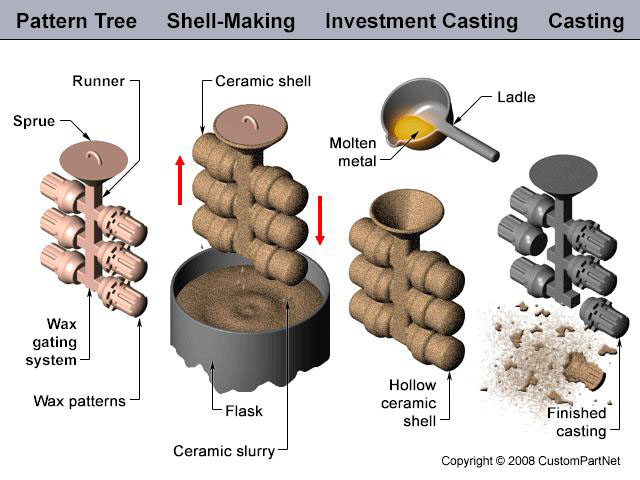

Investment Casting is regarded as a precision casting process to fabricate near-net-shaped metal parts from almost any alloy. Investment casting provides the ultimate technique for low weight precision steel casting production. The benefits of the investment casting process may be summed up by the four words – accuracy, versatility, integrity and finish. Few, if any, alternative metal forming methods can offer such a unique and broad spectrum of advantages.